Inside the Making of a 50-Foot Giant Christmas Tree: US-Made Excellence

- Richard JONES

- Jun 18, 2025

- 3 min read

The Spectacle Starts Here

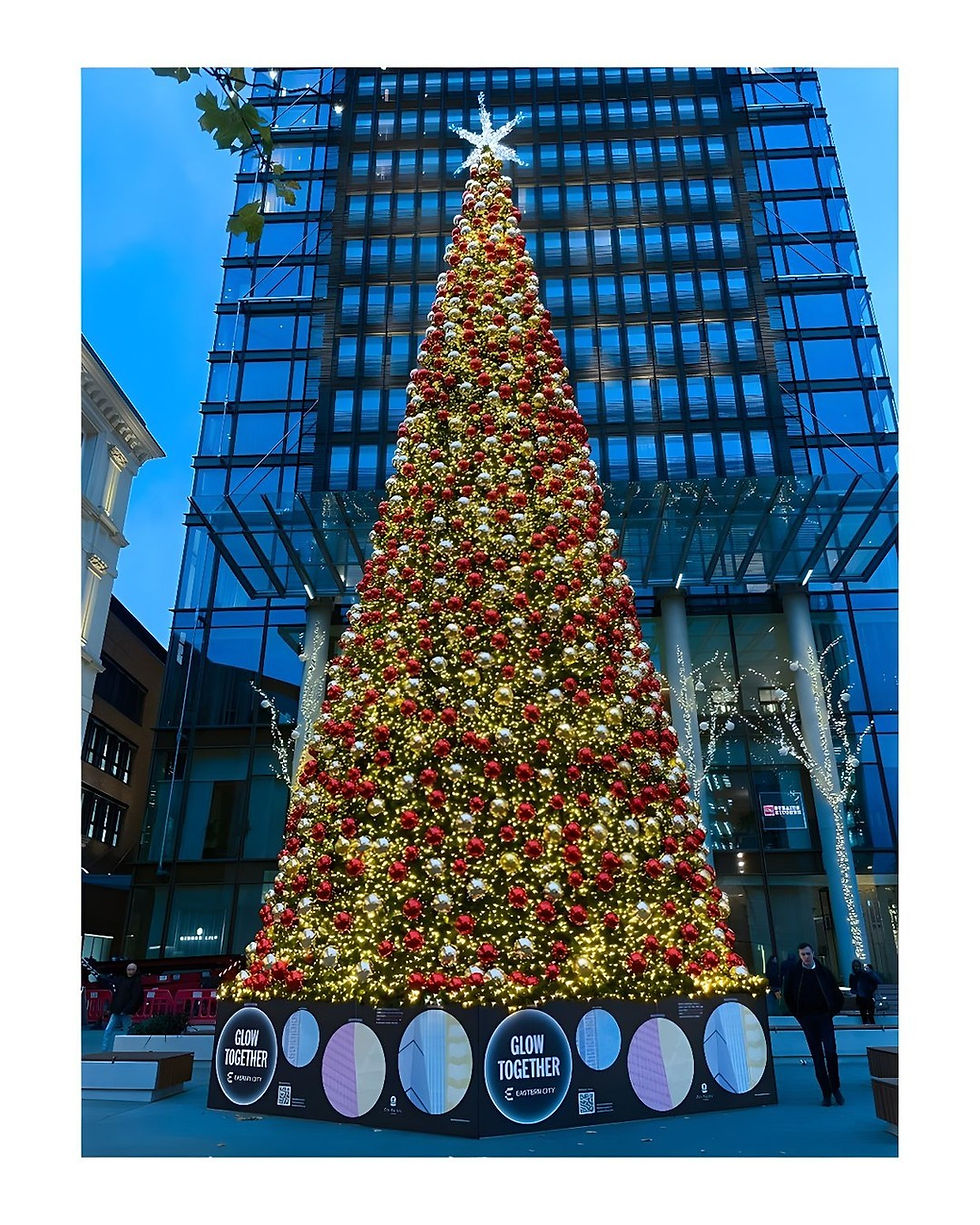

Few holiday installations stop crowds in their tracks like a 50-foot commercial Christmas tree sparkling against a winter sky. Those gasps of wonder aren’t accidental—they’re engineered. Every bolt, branch and LED in our Colorado-made trees is purpose-built for spectacle, safety and long-term return on investment. Today we’re lifting the skirt on the process, materials and people behind the world’s most robust giant Christmas trees.

Roots in the Rockies

In 2005, The Christmas Decorators began manufacturing and installing large-scale trees worldwide—everywhere from Universal Studios in Burbank to the original Bethlehem (yes, that one). By 2024 demand out-paced the holiday installation window, so founder’s son Joe Bolton and long-time colleague Braeden Peterson launched The Giant Christmas Tree Company in Glenwood Springs, Colorado. Their mission: deliver trees from 25 ft to 50 ft that clients can install themselves, grow year-on-year and maintain with minimal fuss.

Steel That Laughs at Winter

When you order a 40- or 50-ft tree, you’re essentially buying a temporary building. That’s why our frames are powder-coated structural steel rated to withstand sustained 68 mph winds. Sections nest together for storage and truck efficiently on standard 40-ft flatbeds. Each tree arrives in modular 5-ft rings: start at 25 ft this year and add more rings in future seasons without replacing the original frame. Even better, anything 40 ft or under can be erected with a standard boom lift—no 100-ton crane needed.

“Our frames are over-engineered because the holidays shouldn’t rely on good weather.”—Braeden Peterson, Co-Founder

Greenery That Stays Green

Cheaper PVC foliage turns blue-green or even grey within two seasons of sun exposure. Ours uses UV-stabilised PVC wrapped around a galvanised steel core, so colour stays evergreen for up to a decade. Steel needles won’t snap in sub-zero temperatures or bleed rust onto plaza pavers. Combined with American manufacturing standards, your maintenance budget just breathed a sigh of relief.

Dual-Chip LEDs: Two Colours, Twice the Impact

A 50-ft model wears 53,400 LEDs—and every single bulb is a dual-chip powerhouse. Inside each lens sit two independent emitters, allowing you to toggle:

warm white → ice white

warm white → multi-colour

…literally at the flick of a controller. These bulbs run 50,000 hours with < 5 % lumen loss after 5,000 hours, thanks to high-grade epoxy that resists yellowing. They’re also:

Low-voltage (24 V) → safer in rain or snow

Double-insulated copper cable → zero bare conductors

Encapsulated in high-performance resin → moisture can’t reach the semiconductor

Your electric bill will thank you, too: dual-chip strings draw just 4 W per 9-ft section.

Beyond the Tree: Bases, Stars & Branding

Modular Bases

Need extra height or a prime sponsorship surface? Our steel hexagon bases add 2–6 ft and come clad in reusable DiBond panels you can reprint each year.

Star Toppers

No tree is complete without a crown. Choose from three designs in two sizes:

Budget fibreglass—flat, paintable, optional LEDs

Rustic plate steel—industrial vibe in gold or silver patina

Signature 3-D LED star—our bestseller, wrapped in sparkling diodes

Whichever you pick, we supply the mounting hardware and safety cabling.

Logistics & Support: Simple as 1-2-3-4

Call for availability—lead times vary from 4–12 weeks depending on size.

Receive PO & invoice detailing height, LED colour, addons, delivery date and freight cost.

Pay 50 % deposit to trigger frame fabrication.

Final coordination call one week before shipping to lock in off-load and assembly timetable.

Sustainability Snapshot

Modular growth means you expand the same tree instead of replacing it—less steel, less PVC, less landfill.

Low-energy LEDs reduce power draw by up to 70 % versus incandescent retrofits.

Made in Colorado for US projects, eliminating trans-Atlantic freight and slashing CO₂ miles.

Quick-Fire FAQ

How long does it take to assemble a 40-ft tree?About six hours with a four-person crew familiar with scaffold towers.

What wind speed can the frame handle?Lab-tested to 68 mph sustained winds, equivalent to a strong gale.

What warranty do I get?Five years on the frame and two years on LED strings as standard.

Can I rent instead of buy?Rentals are limited to select markets—call for a quote.

Ready to Light Up the Skyline?

Imagine crowds gathering for the countdown, the switch flicked, and 50 feet of brilliance blazing above their heads. If that sounds like your downtown plaza, theme park or shopping mall, email Joe at joe@giantchristmastrees.com or visit giantchristmastrees.com to lock in your production slot. Early birds can still secure delivery before Thanksgiving.